SPAce exploration Research for Throatable Advanced eNgine (SPARTAN) project exploits both the throttling capability of the propulsion system and the peculiar characteristics of hybrid engine technology. The development includes the establishment of an advanced coding capability, enabling the definition of the fuel and the throttling behavior of the hybrid engine. The Hybrid propulsion technology has been selected, because to its peculiarities (safety, minimum environmental impact (green propellants), low life cycle costs, responsiveness, competitive performances and increased reliability). www.spartanproject.eu

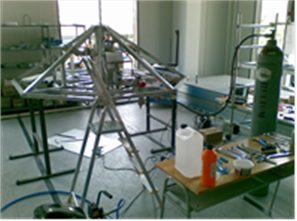

Institute of Aerospace Engineering (IAE) was fully responsible for the platform integration and structural testing, see Figure 1.

Figure 1 – Spartan integration and testing activity at IAE BUT

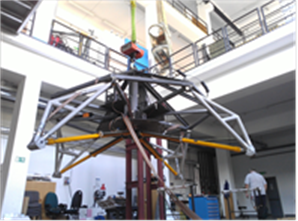

IAE aircraft testing laboratory is capable to perform most complex tests including vacuum and cryogenic temperatures system tests, stability and performance flight tests, complex structural tests including drop tests and impact tests. IAE performed drop tests in own facility and also support firing tests in Figure 2 and 3.

Figure 2 – Drop test facility for aerodynamic stability and firing test of Spartan platform

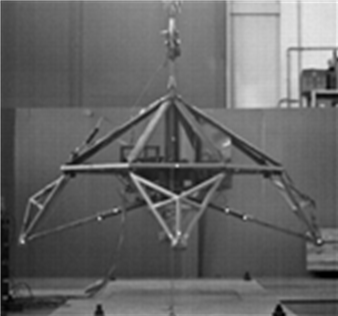

Figure 3 – Final assembling at IAE and structural landing gear drop testing

There is also at the IAE BUT disposal newly built facility for integration and manufacturing. The workshop is organized according to aerospace production and testing rules, practices and cleanliness demands, see Figure 4.

Figure 4 – Integration and testing of Spartan platform