The mission of the European Space Agency’s (ESA) PLATO project is to search for Earth-like planets in deep space. The probe is scheduled to enter orbit in 2026. A Czech company, OHB Czechspace, is also contributing to its development. In July, its engineers, in cooperation with a team from the Institute of Aerospace Engineering at the Brno University of Technology, conducted a unique stress test. The goal was to verify whether the probe’s main structural component, its central tube, could withstand extreme pressure during the rocket launch and the subsequent eight-year mission in space.

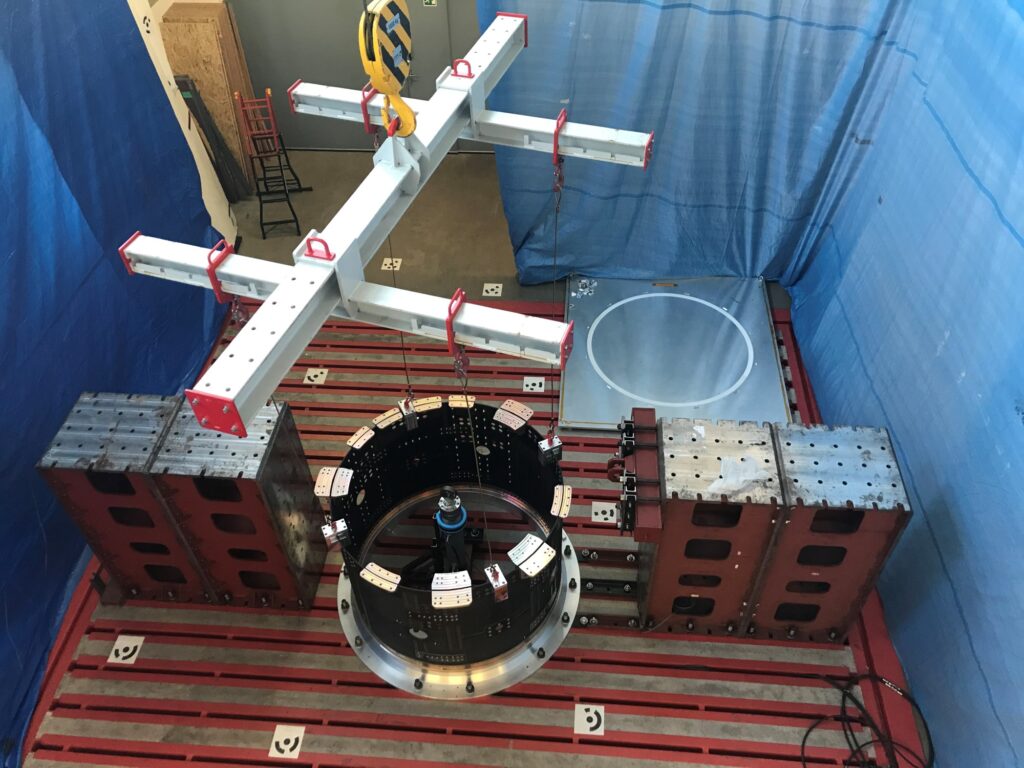

“As part of the test, the central tube had to endure a pressure force of 15 to 20 tons, applied from above and the sides by hydraulic cylinders. The entire structure weighs only 63 kilograms, and its walls are just four millimeters thick. To put it in perspective, we subjected it to the equivalent weight of about 15 passenger cars. The structure must withstand a similar pressure during the launch into space. We will evaluate the test data in the coming weeks, but we can already say that the test was successful,” explained Daniel Rohel, head of the OHB Czechspace analytics team.

The central tube is the primary load-bearing component, effectively the backbone of the entire probe. It has two main functions: it houses the fuel tanks at its core and enables the attachment of the probe to the rocket, which will carry it into space. All the forces exerted by the rocket during launch must pass through this structure. The PLATO probe features a prototype of a specially designed lightweight structure made from carbon fibers, ensuring its rigidity and durability.

“It is a significant step that we were able to conduct the test directly in Brno, and in collaboration with the academic sector. Our task was to prepare, manage, and analyze the stress test. This also meant calculating and modeling the various conditions the probe might encounter in space. Each probe is unique in its design. PLATO will carry a total of 26 optical cameras into space, and its structural properties must be adapted accordingly,” added Rohel.

The preparations for the structural load test of the PLATO probe lasted over a year and a half. They involved designing and manufacturing the necessary testing equipment, performing detailed calculations of the structure’s behavior, and conducting analyses to prove that the tube would not be damaged during the test. The test had to meet the strict standards set by the European Space Agency.

“The actual load application only lasts a few minutes and gradually increases to its maximum level. With the help of highly sensitive sensors, we can detect even microscopic changes and deformations. Together with OHB Czechspace, we have built a well-coordinated team capable of answering all research questions in real-time and strictly adhering to the testing schedule,” said Ivo Jebáček, head of the Aerospace Testing Facility at the Institute of Aerospace Engineering, Brno University of Technology.

“At the Aerospace Testing Facility, we test dozens of different prototypes each year, encountering a wide range of challenges, but our greatest satisfaction comes from seeing our test results materialize into a functional device. In this case, that moment will be when PLATO reaches its orbit around the second Lagrange point,” Jebáček added.

The PLATO mission aims to answer the question of whether Earth-like planets exist. Its objective is to search for planets orbiting bright stars other than the Sun, known as exoplanets. The probe will be equipped with 26 cameras to observe thousands of stars and analyze their brightness. It will transmit data back to Earth from a distance of 1.5 million kilometers. The probe will weigh around two tons and must endure both the launch and an eight-year stay in space without damage.

In the coming months, the central part of the probe will undergo additional tests, including vibration tests. Several companies are involved in its development for the European Space Agency. The central tube was manufactured by the German company INVENT GmbH, which specializes in lightweight composite structures. OHB Czechspace is responsible for preparing the structural analysis of the central tube and coordinating the stress test.

Press release from OHB Czechspace, media contact:

Jana Běhalová, +420 777 999 584, jana.behalova@ohb-czech.cz.

OHB Czechspace

OHB Czechspace, based in Brno, is part of the OHB SE technology group. It specializes in the development of space probes, satellite adapters, and ground support equipment. The company has secured several contracts within the European Space Agency’s programs. In addition to the PLATO mission, it also collaborates on the planetary defense mission Hera and the CO2M mission for measuring carbon dioxide in the atmosphere. More information is available at www.ohb-czech.cz.

Original (CZ): Poletí hledat známky života. V Brně testovali hlavní nosnou část vesmírné sondy PLATO ▪ FSI VUT v Brně